Power sanders are essential tools for many woodworking projects, but their use can often lead to unwanted marks on the surface of the wood. Avoiding power sander leaving marks is crucial for achieving a professional, smooth finish. This thorough guide will cover everything you need to know to prevent surface damage and achieve superior outcomes. We’ll delve into the reasons for these marks, discuss preventative measures, and show you how to use the right tools and techniques. Let’s dive in and uncover the secrets of perfect power sanding!

Understanding the Causes of Power Sander Marks

Power sanding marks often stem from a combination of factors, including improper sanding technique, unsuitable sanding grit, and insufficient surface preparation. Understanding these underlying causes is the first step toward preventing damage. Using an inappropriate sanding grit can lead to uneven surfaces. If you apply too much pressure, this will also cause scratches and marks.

Inappropriate Sanding Grit

Using the wrong grit sandpaper for the job can lead to uneven surfaces, scratches, and eventually to significant damage. varied wood types and desired finishes necessitate varied grit sandpaper. Using a very coarse grit on a delicate finish can leave significant damage. Conversely, a fine grit might not effectively remove imperfections from a rough surface.

Improper Sanding Technique

Maintaining consistent pressure and avoiding excessive pressure on the power sander is crucial. Uneven pressure and erratic strokes will invariably leave tell-tale marks on the surface. Maintaining an even pace and direction is key to preventing these marks.

Related Post : DIY Paint Job Peeling Early? What Went Wrong and How to Fix It

Surface Preparation: The Foundation for a Smooth Finish

Proper surface preparation before power sanding is paramount for avoiding surface damage. A smooth, even surface will translate directly to a smooth, even finish after power sanding. Poor surface preparation is often the root of problematic power sanding outcomes.

Evaluating the Surface

Before power sanding, meticulously examine the surface for existing imperfections like knots, cracks, or splinters. Address these issues with appropriate woodworking tools before you begin the power sanding process. This initial step significantly impacts the overall outcome.

Removing Imperfections

Using appropriate tools and techniques, remove any knots, cracks, or splinters from the surface. A thorough sanding process using progressively finer grits is often necessary to achieve a level playing field. By removing these imperfections, the power sanding process becomes more efficient and effective, minimizing the potential for marks.

Choosing the Right Power Sander for the Job

varied power sanders cater to varied needs and projects. selecting the appropriate tool is essential for achieving a consistent and quality finish.

Choosing the Correct Orbital Sander

Orbital sanders offer a gentler sanding action, reducing the risk of scratching. This is a good choice for beginners, or for delicate wood surfaces. Adjusting the orbital sander to the appropriate speed for the material will ensure a good finish.

Choosing the Right Belt Sander

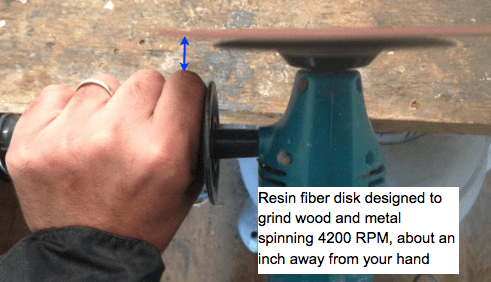

Belt sanders are often preferred for larger areas, allowing for more aggressive sanding. Proper belt sander maintenance is key to producing a consistent sanding action. However, these should be used cautiously on delicate finishes to avoid leaving visible marks.

Power Sander Technique for Optimal outcomes

Utilizing the proper technique with your power sander drastically reduces the risk of surface damage. The method you use will significantly impact the quality of the final surface.

Maintaining Even Pressure

Apply even pressure throughout the sanding process. Avoid applying excessive or inconsistent pressure, as this is a primary cause of marks.

Avoiding Repetitive Strokes

When sanding, always move in a consistent direction; moving back and forth on the same spot will lead to defects. Cover the entire surface in a series of overlapping strokes, ensuring all areas are addressed equally.

Maintaining Optimal Speed

The speed of the power sander can affect the outcomes. Start at a slower speed to avoid excessive pressure or marks, then adjust as needed for your project.

Utilizing the Right Sandpaper Grit

selecting the correct sanding grit for the project is critical for achieving optimal outcomes. Every stage of the sanding process requires varied levels of grit to achieve varied levels of surface refinement.

Understanding Grit Sizes

Begin with a coarse grit sandpaper to remove major imperfections and defects. Gradually transition to progressively finer grits for a smooth finish.

Matching Grit to Wood Type

varied wood types respond variedly to various grit sizes. For instance, hardwoods might require a coarser initial grit than softer woods. Experiment to find the appropriate grit for your material.

In summary, avoiding power sander leaving marks requires meticulous preparation, proper technique, and the right tools. By following these steps and understanding the potential issues, you can achieve a smooth, professional finish with your power sanding project. Remember to prioritize safety measures throughout the process, and always select the appropriate grit sandpaper for your specific material and desired outcome. For more advanced projects or intricate details, consider consulting professional woodworking guides. Ready to tackle your next woodworking project without surface damage? Visit our website for more expert tips and tutorials!