Expansion joints failing prematurely can lead to significant infrastructure damage and costly repairs. This article delves into the common causes, preventative measures, and corrective actions to address this critical issue. Imagine a bridge collapsing, or a building cracking due to neglected expansion joints. This is precisely why understanding the mechanics of expansion joints and proactive maintenance are so crucial. This thorough guide offers a detailed overview of the causes, detection methods, and corrective actions to resolve prematurely failing expansion joints and safeguard your infrastructure. We will first explore the fundamental ideas of expansion joints and the common reasons behind premature failures. Following this, we will cover preventative strategies and maintenance protocols, providing specific examples and optimal practices. Lastly, we will examine cost-effective corrective actions to address existing problems.

Understanding Expansion Joints and Their function

The function of Expansion Joints in Infrastructure

Expansion joints are essential components in infrastructure projects such as bridges, buildings, and pipelines. Their primary function is to accommodate the dimensional changes in structures caused by thermal expansion and contraction. Structures are subject to significant thermal fluctuations and without expansion joints, considerable stress would be placed on the structure leading to cracking and failure. By allowing for these changes, expansion joints prevent the development of excessive internal stresses and safeguard the overall integrity of the structure. Understanding the intricacies of these movements and their effects is crucial in developing effective preventative and corrective strategies to ensure long-term structural integrity.

Common Types of Expansion Joints

Several types of expansion joints are employed based on the specific requirements of the project. These include: roller expansion joints, sliding expansion joints, and filled expansion joints. Each type has its own unique characteristics and is suited for particular applications, thereby contributing to the complex process of mitigating stress in structures.

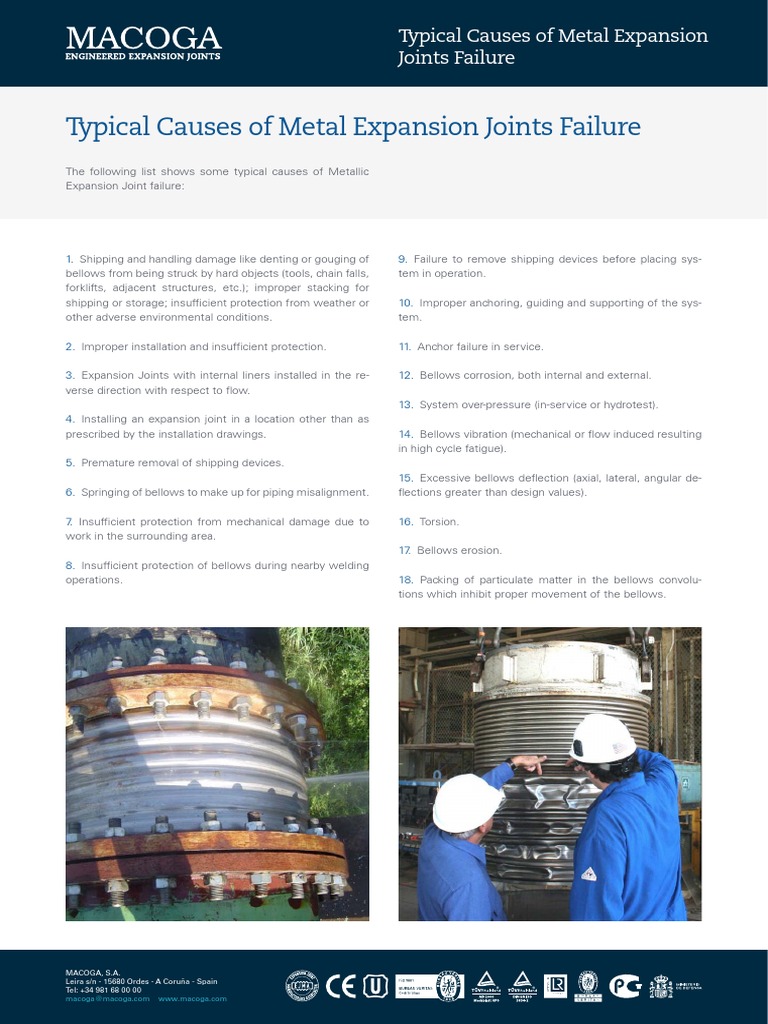

Common Causes of Premature Failure

Premature failures can stem from various issues, including inadequate design, poor installation, and insufficient maintenance procedures. The type of material used, environmental factors, and the nature of the load bearing stress can also influence premature failure. Understanding these factors is key to developing thorough mitigation strategies. This is critical for the achievementful long-term operation of any infrastructure.

Related Post : Uneven Walkway Creating Tripping Hazard? Solutions to Level Safely

determineing Premature Expansion Joint Failures

Visual Inspection Techniques

Regular visual inspections are crucial to detect potential problems early on. determineing cracks, misalignments, or signs of excessive wear and tear is paramount. Inspection protocols should adhere to established industry standards, including using specialized tools to access hard-to-reach areas. Visual assessment is often the first step in determining the extent and cause of failure and is an crucial cost-effective preventative plan.

Monitoring for Movement and Settlement

Expansion joints frequently demonstrate movement and settlement issues. Advanced monitoring techniques using sensors and other technology can track the performance of these components and offer an objective overview of any unusual behavior that indicates potential failure or damage. Proactive monitoring often helps predict and mitigate damage before it escalates.

Evaluating Material Degradation

Corrosion, weathering, or other types of degradation can significantly impact the integrity of expansion joints. Testing materials for degradation and potential failure is an crucial part of preventative maintenance and can often suggest areas of improvement before it is too late and prevent costly replacements.

Preventing Expansion Joint Failures

Effective Design Strategies

The design of expansion joints plays a pivotal function in ensuring their longevity and functionality. A proper design considers factors like material selection, load capacity, and environmental influences, thereby reducing the risk of premature failure. Engineers should consider the use of sustainable materials for long-term performance to minimize environmental damage and maintenance.

Corrective Actions for Existing Failures

Repair Techniques for Damaged Joints

When expansion joints fail, corrective measures are necessary to restore structural integrity. These procedures should be carried out by qualified professionals to ensure the implementation of appropriate repair techniques and the long-term efficacy of the repair. Often, a deep dive into the root cause is needed to inform and justify the cost-efficacy of these repairs.

Maintenance Protocols for Proactive Management

Regular Inspections and Maintenance Schedule

Proactive maintenance is critical for the longevity of expansion joints. A well-defined maintenance schedule, involving routine inspections and necessary repairs, can significantly reduce the risk of premature failures, saving money and preventing costly damage to the infrastructure. These inspections can determine areas for potential improvement in the design and material components of the expansion joint and prevent costly failures before they occur.

In conclusion, premature expansion joint failures are a significant concern in infrastructure projects, impacting both safety and cost-efficacy. Understanding the root causes, implementing preventative measures, and incorporating regular maintenance protocols are crucial for mitigating this risk. Contact a qualified structural engineer or consulting firm for a thorough assessment and tailored solutions to ensure the longevity and integrity of your expansion joints. This article has explored the key facets of expansion joint failure; now it’s your turn to take action!